AEG PLC-Migration – Latest technology and protection of existing investments

Do you operate an AEG PLC system with the systems A120, Compact, A250, A130, A350 or A500? Then you can look into the future with confidence, because OHP offers, in addition to spare parts and new parts for your proven AEG PLC system, a cost-effective, reliable and long-term available option to upgrade your AEG PLC system to the latest state of the art.

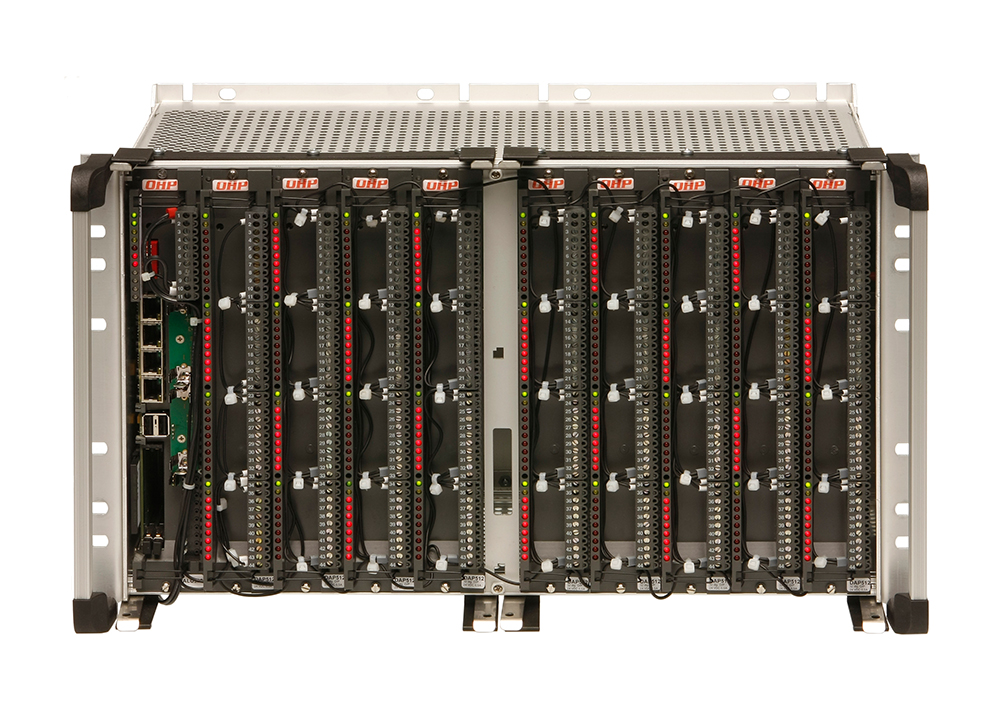

With the OHP systems @120 and @250, new products are available which migrate the A/U devices from AEG/ Schneider into a new and long-term available automation and telecontrol series from OHP at minimized cost and time. The impressive advantage of this strategy is the cost saving by using existing peripherals such as I/O modules and KOS modules with existing wiring: Only what needs to be replaced is replaced.

Especially for production plants, the high availability is a decisive advantage when renewing with OHP modules. Commissioning with the compatible OHP modules can be carried out quickly and planned reliably. There is no point of no return, since the system is ready for operation again simply by changing the modules.

Success Stories (German)

Customers from a wide range of industries have been using OHP telecontrol and automation solutions for many years. Find out more:

Advantages of an AEG PLC migration to OHP @120 or @250

With AEG migration, your systems experience added value that is characterized by IEC conformity – IEC 60870-5-101 /-104 protocols, IEC 61131-3 programming – and the opening of the system for external expansion. As a rule, only the ALU and backplane need to be replaced, making the standardized IEC 60870-5-101 /-104 procedures with modern programming technology available under IEC 61131-3.

By using the existing KOS modules, there are elegant upgrade possibilities from SEAB 1F and SEAB 1W procedures to standardized IEC procedures.

- Retention of the existing AEG PLC I/O level

The impressive advantage of this strategy is, among other things, the retention of the existing I/O level. This eliminates high costs for new I/O modules during assembly and wiring as well as for documentation and training. This means that a modernization of the system can be realized with considerably lower and manageable costs and time expenditure.

- Carrying out a modernization during operation

The implementation of a modernization during ongoing operation can be calculated exactly, as there is no „point of no return“. If the system to be modernized has to be put back into operation at a certain point in time, the previous ALU and, if necessary, the basic subrack can be simply plugged in if necessary.

- Upgrade to modern programming technology and communication interfaces

In addition to the upgrade to modern programming technology and communication interfaces, the @120/@250 modernization of an existing A-device automation system provides added value that ensures the long-term use of the system.

- Added value through new standardized IEC 60870-5-101/-104 or Modbus procedures with modern programming technology under IEC 61131-3

Usually only the ALU needs to be replaced, making the new standardized IEC 60870-5-101/-104 or Modbus procedures with modern programming technology under IEC 61131-3 available.

- Elegant upgrade strategies from SEAB 1F and SEAB 1W procedures to standardized IEC procedures

By using the existing KOS modules, elegant upgrade strategies from SEAB 1F and SEAB 1W procedures to standardized IEC procedures are possible.

- Development of new technologies and extension of functionality by using modern components

- Long-term availability of all modules

- Further use of existing AEG PLC spare parts

Further information can be found in the document „Guide to renewal“:

Talk to us, we will modernise your plants and secure your investments in the long term.

Digital system solutions for infrastructure and industry

About OHP

OHP GmbH from Rodgau is a system supplier for automation, telecontrol and control technology. We offer our customers products and services for the infrastructure, energy and industrial plant sectors, and rely on integrated system technology and open communication standards for safe and economical long-term operation.

Experience and quality since 1989

OHP’s employees combine the know-how of more than 30 years. Having emerged from an AEG development department, we are one of the few companies that can draw on a product portfolio developed in-house, ranging from telecontrol/automation devices to open communication technology and control systems with additional packages.

OHP stands for investment protection and innovative system solutions as well as tailor-made engineering and services for the benefit of our customers. OHP has been working to recognised quality standards for years and is certified to ISO 27001:2017, ISO9001:2015, SCC occupational health and safety and other standards.

System solutions for a digital infrastructure

- Control technology and station control systems for energy, water, sewage, infrastructure and industry

- System solutions for virtual power plants and EEG feed-in management

- Telecontrol and automation technology

- Communication technology from modem module to protocol converter with powerful communication functions

- IT- Security, secure complete solutions for the certification according to ISO 27001

- Railway technology from stationary current monitoring to the automation of rail vehicles

- Turnkey systems from planning and execution to training and support

- Electronics / software development / manufacturing for OEM assemblies

Are you interested in an AEG-PLC migration to OHP @120 or @250?

Your contact person:

Sebastian Ott (M.Sc.)

OHP Automation Systems GmbH

Gutenbergstr. 16

63110 Rodgau (Germany)

Phone.: 06106-84955-0

More info on www.ohp.de

Yes, I have taken note of the data protection declaration and agree that the data I have provided may be collected and stored electronically.

My data will only be used strictly for the purpose of processing and answering my inquiry.

By sending the contact form I agree to the processing of my data.